|

Index...

|

oventry has always been a hotbed for trying out new technology and ideas, right back to 1868 when Rowley Turner brought a French velocipede cycle back from the Paris Exhibition to his uncle Josiah, manager of the Coventry Sewing Machine Company in Coventry. They soon began to make copies, improving on the design and giving birth to the cycle industry and the development of the cycle we have today. It was Coventry that the German Daimler company chose, to set up the first British manufacture of motor cars, because of its skilled and technically minded work-force.

oventry has always been a hotbed for trying out new technology and ideas, right back to 1868 when Rowley Turner brought a French velocipede cycle back from the Paris Exhibition to his uncle Josiah, manager of the Coventry Sewing Machine Company in Coventry. They soon began to make copies, improving on the design and giving birth to the cycle industry and the development of the cycle we have today. It was Coventry that the German Daimler company chose, to set up the first British manufacture of motor cars, because of its skilled and technically minded work-force.

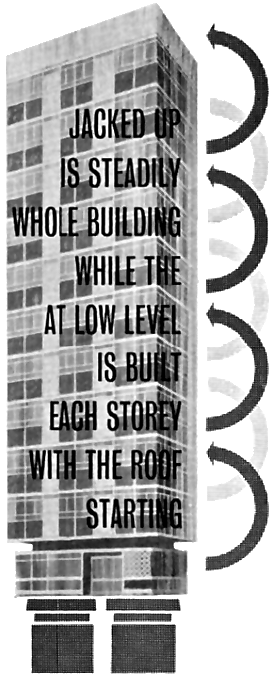

So again, when the inventor Jansz Joost Werner, from The Hague in the Netherlands, came up with a new novel way of building fast and cheap tower blocks of flats, he came to Coventry. Working with Richard Costain of Costain Construction Ltd., his idea was to build the roof and top floor first at ground level on a large number of jacks. It would then then jacked up and another floor built underneath it. What is now a two story block is jacked up another level and the third floor and walls built underneath, and so on.

The jacking device acts directly on the central core structure which, together with the projecting floors, provides a substantially rigid structure. The jacks raised the building at a rate of half a metre an hour! When all the floors are completed it is then anchored to the foundations, it was known as the 'Jack-Block' system.

So why build it in Coventry? The city was a 'boom town' in the 1950s and '60s with full employment. Loads of people came to Coventry to work, so housing was in very short supply. The Coventry County Borough Council were on the largest building programme in history and one and two bedroom flats were very much needed. So, if they could be built quickly and cheaply the council would try it.

The world's first building to be built using the Jackblock system was Alpha House in Barras Heath in 1963.

It came as a light bulb moment when I realised why this 17-storey residential tower block of 97 flats was named 'Alpha House'. Alpha is the first letter of the Greek alphabet and is used to designate the first of its kind - and Alpha House is the first of its kind!

What are the advantages of building the Jackblock way? Besides being quick and cheap, the building would be built on site in a factory type of way giving the advantages of being able to work in all types of weather, as it was the roof that was built first. Heating and lighting could be easily available and all trades working on the ground level meant they did not have to have loads of scaffolding, or heavy cranes and hoists to get workers and materials up and down the building. As each floor was completely built it would then be jacked up and the process would be repeated over and over again. Each floor could be completed in about a week, so 16 floors would only take 4 months, then after final fitting the building could be ready in around 5 to 6 months.

What are the disadvantages? The building process relied on all materials and trades people arriving on site and doing their work in a systematic sequence and on time before the floor was jacked up. If there was any delay or work not completed it could become very expensive, especially if the fault was high up on the outside of the building.

In 1963 the Costain company put out a Press Release: "No Freeze at Jackblock - In the Artic weather which has gripped the whole country since Christmas and reduced building site activities considerably, normal working has continued on Costain's Jackblock site in Coventry. No men have been laid off, there has been no short time working, and building progress has been maintained to schedule. Any construction method which can continue in such severe conditions is of immense importance at this time of housing shortage and unemployment. The project is a 17-storey block of flats for the Coventry Corporation, and is a prototype for the Jackblock method of construction. One of its important features is the introduction of factory conditions to abiding site. Cladding of the upper floors is completed at low level so that the finishing trades operate in the dry, and surrounding the three lower floors is a large plastic tent which keeps out the weather, and blower heaters are installed for use when it is cold. This innovation was warmly welcomed when the Jackblock system was launched last year, and this winter's dress-up then tested its efficiency. In the event its worth has been amply proved. With the site covered with snow and temperatures below freezing point, the pouring of concrete is completed without a hitch. The men like the system because their employment is continued regardless of weather conditions, and absenteeism has been cut to a minimum."

There have been approximately 10 buildings in the world which have been built using the system since 1963. Mercia House in the Lower Precinct was the second one in Coventry.

So, when I was looking for architectural firsts I was pleasantly surprised to find that in 1963 the very first block of flats to be made where the roof and the top floor are made first was Alpha House, the 'Jack Block' system way.

Unfortunately, in 1998 a father and son died due to a mentally ill neighbour setting fire to her flat next door, who survived, but the smoke spread into Mr Redshaw and his son Richard's bedrooms in the flat, causing brain death due to the lack of oxygen. The lack of fire alarms and poor fire containment was blamed.

In 2010, nearly fifty years after the building was erected, Alpha House was renovated by the Whitefriars Housing Group at a cost of £1.97 million. The building was over-clad with aluminium panels, and windows were replaced. A Press Release by the Whitefriars Housing Group (now called Citizen Housing) read; "The external refurbishment of Alpha House went extremely well and we are delighted with the outcome, which provides high quality accommodation for our tenants". Hopefully it now complies to all the safety requirements.

Early in 1962 Richard Costain (Contractors) Limited started work on the construction of a 17-storey block of flats in Coventry, by a unique method known as Jackblock. By this method, devised within their own organisation, the roof is constructed first at ground level and raised by hydraulic jacks. Supporting walls of the roof and the top storey are constructed beneath the roof and the whole structure jacked up to allow the same sequence of construction and lifting to be carried out for each successive storey, until the whole building has been built and lifted into its final position. In simple terms, the block, starting with the roof, is extruded upwards from an assembly plant at ground level.

The building is constructed upon a structural hollow core which houses the services, lifts and staircase. It is under the core that the main lifting jacks are situated and each floor slab is cantilevered out from the core on each of its four sides. The construction of each floor is based on four pre-tensioned concrete beams supported directly on the walls of the core and intermediate spaces between the main beams are infilled with secondary concrete beams.

The first operation, after putting in the foundations (which are piled at Coventry) is the excavation and construction of the jacking chamber. Next, the ground floor slab is cast to serve as a temporary floor shutter for all the upper floors. The roof slab is next constructed on the ground slab and the penthouse built on top. At this stage the lift motors and tanks can be placed in position. The core, constructed from concrete blocks and then made homogeneous by filling the spaces between the blocks with concrete, is built on a series of hydraulic jacks, each of 220 ton capacity, in the jacking chamber, and on this core the roof slab and penthouse are raised to first floor level.

Jacking is carried out in steps of 7½ ins. The whole structure is raised by this amount and each of the 40 jacks is lowered in turn and a further course of concrete blocks inserted. When this course is completed the jacks came the core one more course. The process is repeated until the whole structure is lifted a full storey height. Jacking takes place every other week; during the 'rest' week the next floor slab is made at ground level. The rate of jacking is about one inch every three minutes. The operation is extremely accurate and a high degree of control is maintained. The jack layout is such that some of them act as compensating jacks giving stability during the lifting period, and vertical alignment is ensured even in high winds.

The top floor slab is next completed and the building jacked up the equivalent of a further floor height. Subsequent floors are assembled at ground floor level and the building jacked up the same way each time. As the structure rises from the ground, it passes each of the finishing trades, which are located at various levels, like a vertical assembly lane. At first floor level partitions are placed in position and first fixings, floor screeds and plumbing are put in. At second floor level, plastering and cladding are carried out and at third door level the second finishes and painting. Floor finishes are laid at fourth floor level.

Three levels of scaffolding, clad in polythene sheeting, form the air-conditioned factory through which the building is extruded and in which work continues unaffected by weather. As a storey rises above the fifth floor level it is complete and theoretically habitable.

Advantages of Jackblock. The concept of completing building operations near ground level should save time and money for these reasons: men and materials are not required high above ground level; progress is unaffected by bad weather once foundations have been completed and the roof slab made; the finishing trades operate concurrently with the formation of the structural frame; detailed planning and integration of supply of materials and site operations ensure a vigorous timetable.

Jackblock is particularly suited to the construction of tall cantilever buildings, and will show to best advantage where such buildings are required, e.g. in earthquake areas (United States, Pacific coast, Japan; on unstable ground (Mexico City, Singapore); in areas where mining subsidence may be expected; on made up or reclaimed ground (e.g. harbour areas). If such a building subsequently tilts, it can be re-aligned by the re-insertion of Jacks.

Jackblock can be used in the construction of buildings having widely different shapes in plan; among projects on the drawing board are a multi-storey office block, rectangular in plan, and a block of flats in a mining subsidence area.

It is expected that Jackblock will open a new era in multi-storey construction and will supply the solution to many architectural and technical construction problems which are not solved by conventional building methods.

Website by Rob Orland © 2002 to 2026